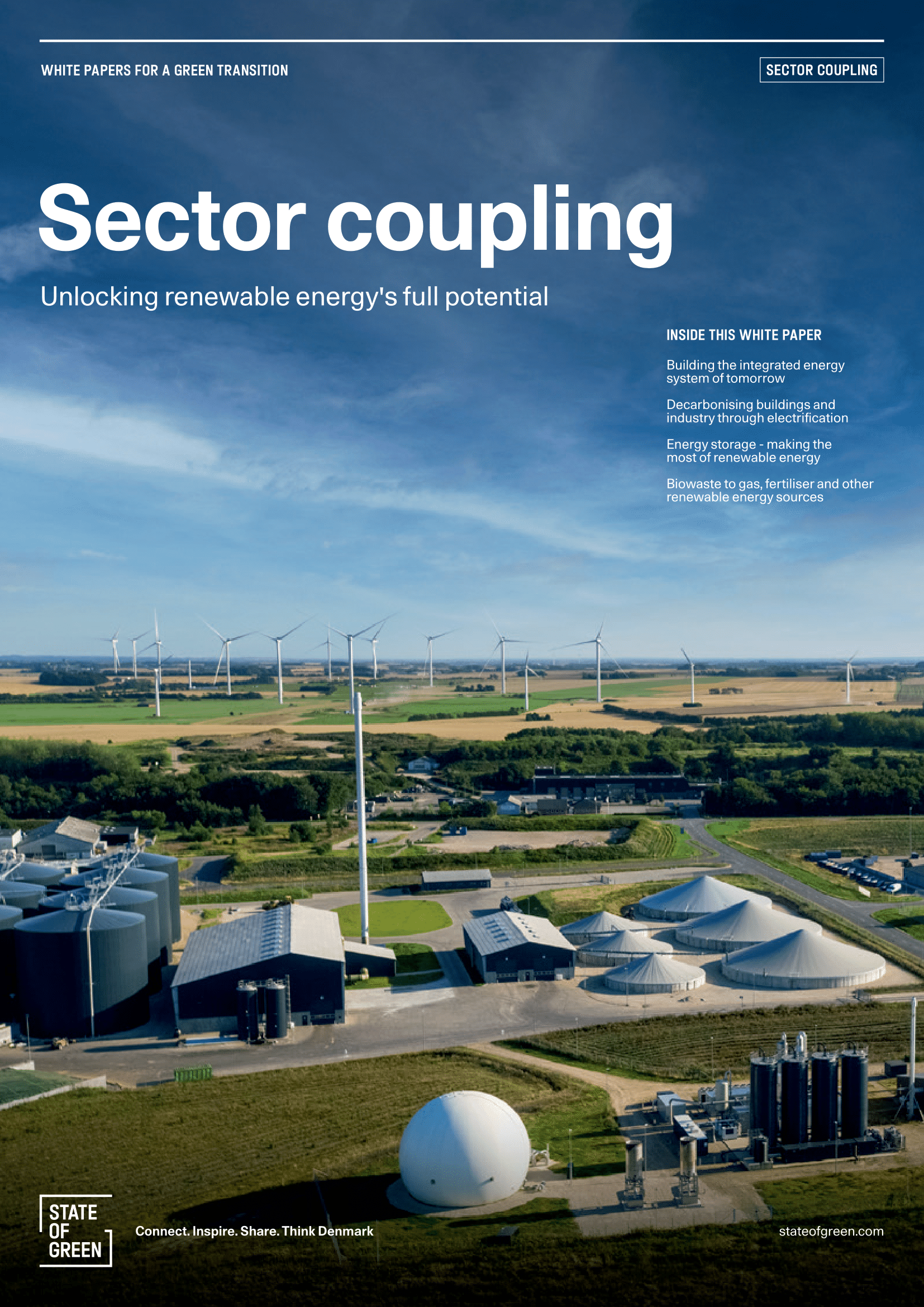

Sector coupling is emerging as one of the most transformative approaches to accelerating the green transition. By linking traditionally separate sectors such as energy, heating, transportation, and industry, sector coupling unlocks significant efficiency gains and resilience, creating new opportunities for sustainable innovation. At its core, this approach breaks down barriers, fostering collaboration and enabling renewable energy to flow seamlessly between systems that were once siloed.

In this article, we explore seven examples from Denmark’s energy and industry sectors, showcasing how digitalisation, energy systems integration, Power-to-X technologies, and more are being deployed to drive energy efficiency, reduce carbon emissions, and boost sustainability. These cases highlight the immense potential of sector coupling in delivering innovative, scalable solutions for a greener future.

Each case represents a step forward in reimagining how sectors collaborate to create a cohesive and sustainable energy system, demonstrating how this approach can make an impact locally and globally. Dive into the examples below and explore the future of sector coupling.