1: Novozymes – Enzymes for sustainable textile care

The fashion industry, a significant contributor to global CO2 emissions and microplastic pollution, faces an urgent need for more sustainable practices. Novozymes, a leader in biosolutions, has developed enzymes that enhance the effectiveness of laundry detergents. These enzymes allow clothes to be washed at lower temperatures while efficiently removing stains, odors, and damaged fibers. By using these enzymes, not only is energy consumption reduced, leading to lower greenhouse gas emissions, but the lifespan of clothing is also extended, which reduces waste. This biosolution exemplifies how biotechnology can directly contribute to a more sustainable textile industry.

2: Biomason – Biocement for low-carbon construction

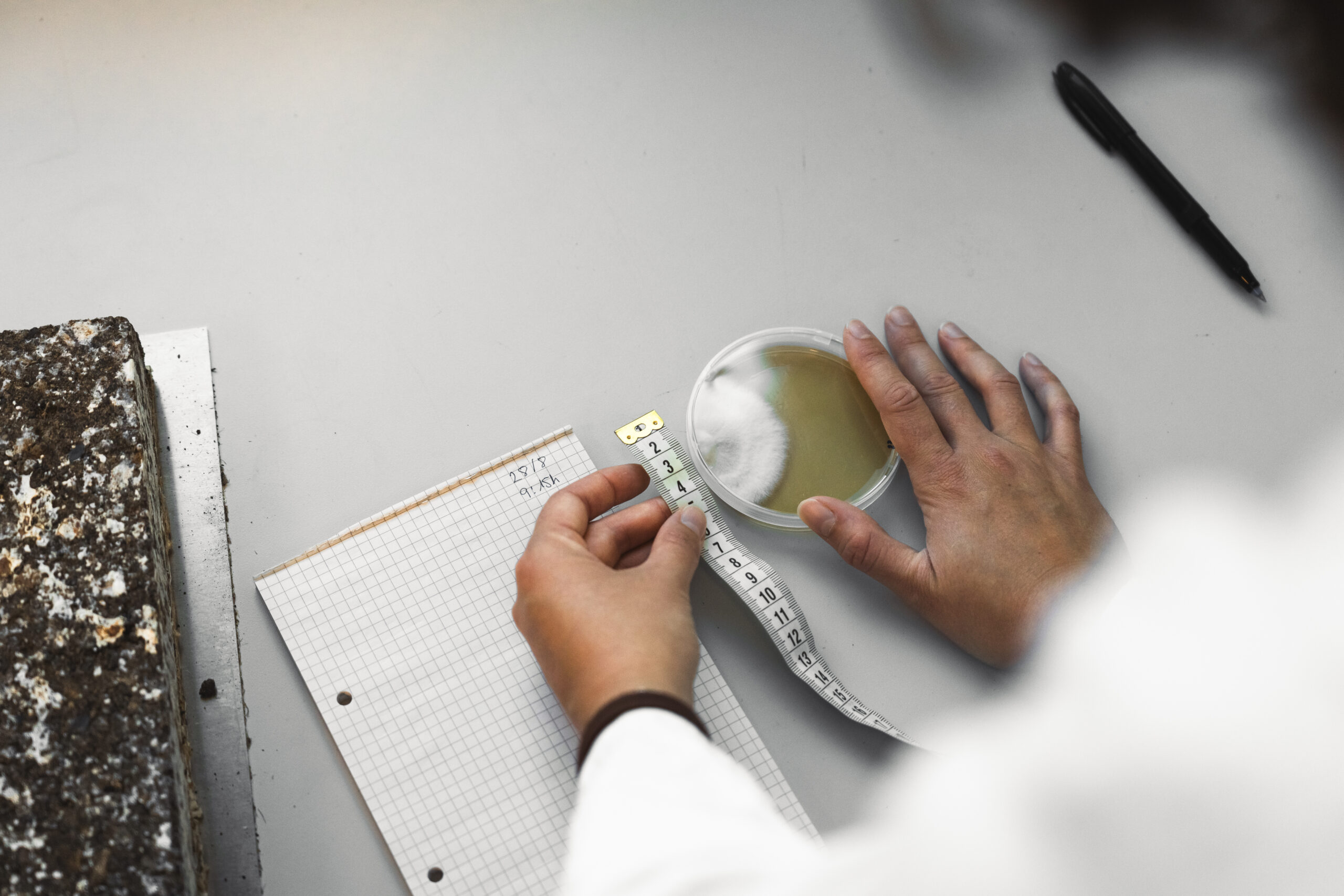

Cement production, a cornerstone of the global construction industry, is notorious for its high carbon footprint. Biomason has tackled this issue by creating biocement through a process inspired by marine ecosystems. By using bacteria to bind sand particles together, Biomason’s method mimics the natural formation of coral reefs. This innovative approach eliminates the need for fossil fuel-fired furnaces and the carbon-intensive calcination process, thereby drastically reducing the environmental impact of cement production. Biomason’s biocement offers a sustainable alternative that could revolutionize the construction industry by significantly lowering its carbon emissions.

3: Pond – Bioplastics from green plants

The global demand for plastic, which contributes significantly to environmental degradation and climate change, continues to rise. Pond, a Danish company, has developed a groundbreaking technology to produce bioplastics from plants like grass and sugar beets. These bioplastics are biodegradable, compostable, and can be recycled endlessly without losing their quality. Remarkably, Pond’s bioplastics also contribute to carbon sequestration, as the plants used in their production absorb and store CO2. This innovation not only reduces reliance on fossil-based plastics but also helps mitigate climate change by capturing carbon.

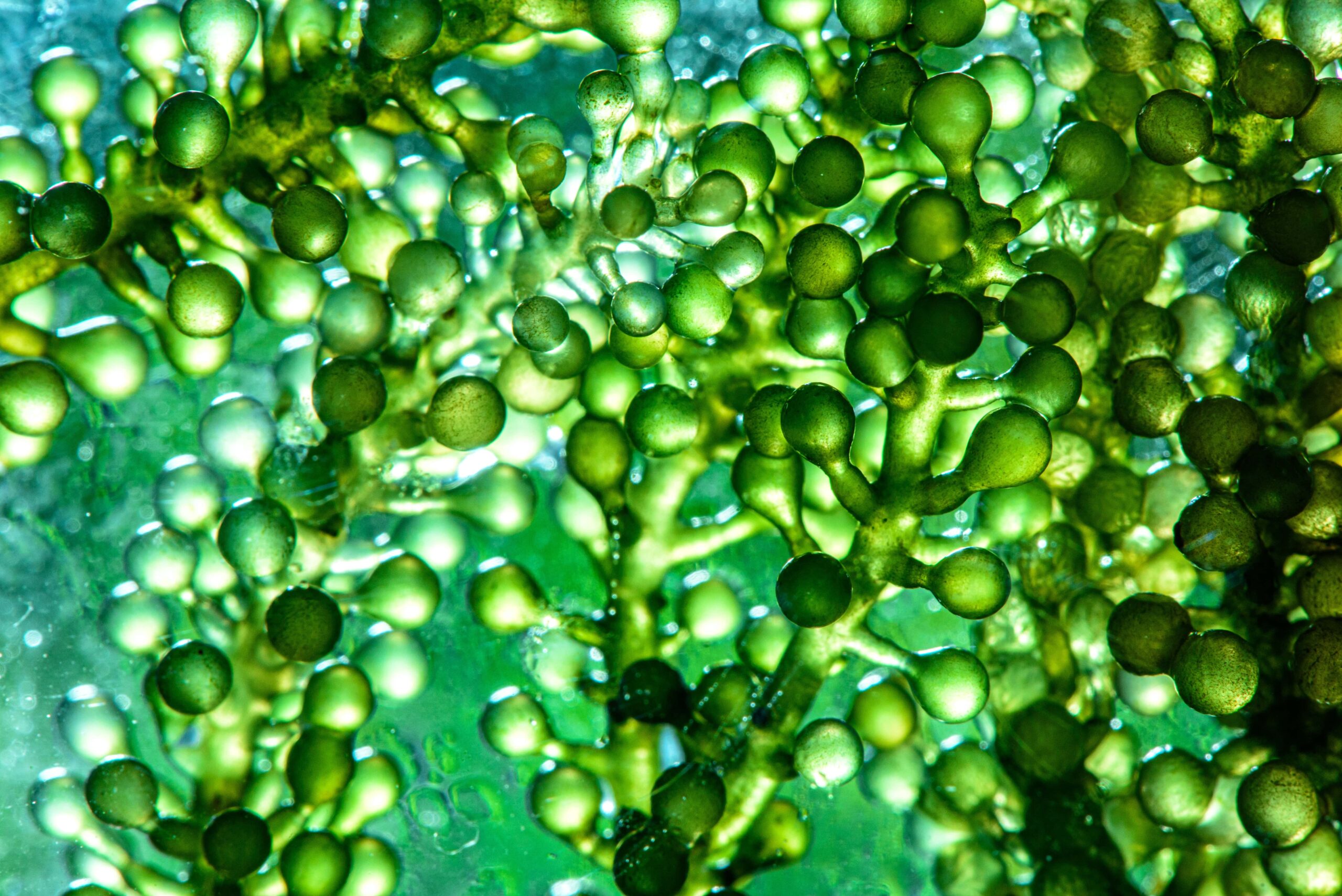

4: Algiecel – CO2-to-food technology for small industries

While large industries have begun adopting carbon capture technologies, small and medium-sized enterprises often struggle to find feasible solutions. Algiecel addresses this gap with its compact photo-bioreactor, which converts industrial CO2 emissions into valuable products like biomass and microalgae oil. These by-products can be used as ingredients in animal feed, human food, and cosmetics. Algiecel’s technology is particularly suited to smaller industries, such as biogas and fermentation plants, offering them a practical and profitable way to reduce their carbon footprint while contributing to a more sustainable food and feed sector.

5: Chr. Hansen – Fermentation for food waste reduction

Global food waste is a pressing issue, with a significant portion of food, especially in the dairy sector, going to waste due to short shelf lives. Chr. Hansen, a leading bioscience company, combats this problem through the use of fermentation with beneficial bacteria. Their extensive range of food cultures helps delay spoilage and the growth of pathogens, thereby extending the shelf life of products like yogurt, meat, and ready-to-eat foods. By applying these natural processes on an industrial scale, Chr. Hansen’s solutions have the potential to significantly reduce food waste, ensuring that more food remains fresh and safe for consumption.

6: MATR Foods – Plant-based meat alternatives

The production of meat is a major contributor to greenhouse gas emissions, which are driving climate change. MATR Foods, a Danish start-up, has developed a new generation of plant-based meat alternatives using fungal fermentation combined with five organic, locally sourced ingredients. These plant-based products are designed to replicate the taste, texture, and nutritional profile of meat, making them an appealing alternative for consumers looking to reduce their meat consumption. By encouraging a shift towards plant-based diets, MATR Foods’ innovations could play a significant role in reducing the environmental impact of food production.

7: Novo Nordisk Foundation + Bill & Melinda Gates Foundation – CO2-to-protein technology

As global food insecurity rises, finding sustainable ways to produce food without relying on increasingly scarce farmland is critical. A consortium funded by the Novo Nordisk Foundation and the Bill & Melinda Gates Foundation is developing a revolutionary technology to convert CO2 into acetate, which is then used as a substrate in fermentation processes to produce food proteins. This approach bypasses the need for agricultural land, offering a scalable solution to feed a growing global population. If brought to full production, this technology could provide a stable and nutritious food source for over a billion people annually, all while preserving natural ecosystems.

8: BioPhero/FMC Corporation – Biological insect control

Agriculture’s dependence on synthetic pesticides has significant negative effects on the environment and biodiversity. BioPhero, now part of FMC Corporation, has developed a biosolution that leverages insect pheromones to control pest populations without harming beneficial insects. These pheromones disrupt the mating process of pests, reducing their populations without the use of harmful chemicals. By scaling this technology, BioPhero offers a sustainable alternative that protects crops and supports biodiversity, helping to create a more sustainable agricultural system.

9: Cysbio – Eelgrass acid for anti-fouling paint

Marine pollution is exacerbated by the widespread use of copper-based anti-fouling paints on ships, which release toxic substances into the ocean. Cysbio, a Danish company, has developed a sustainable alternative by producing eelgrass acid through fermentation. This acid, naturally found in eelgrass, can replace copper in anti-fouling paints, reducing the environmental impact of shipping. Moreover, eelgrass acid holds potential as a replacement for toxic fungicides used in agriculture, further extending its environmental benefits.

10: Aquaporin – Natural water filtration

Access to clean water is a critical issue worldwide, with millions lacking safe drinking water. Aquaporin, a Danish company, has harnessed the power of nature by incorporating aquaporin proteins into water filtration membranes. These proteins, which naturally occur in cell membranes, are highly efficient at filtering water, surpassing the capabilities of man-made filters. Aquaporin’s technology enables industries to recycle and reuse up to 95% of their water, drastically reducing water consumption and pollution. This innovation represents a significant advancement in sustainable water management.